News

EV Li-ion Battery Crushing Recycling Machine

Time:2024-07-12 15:39:23

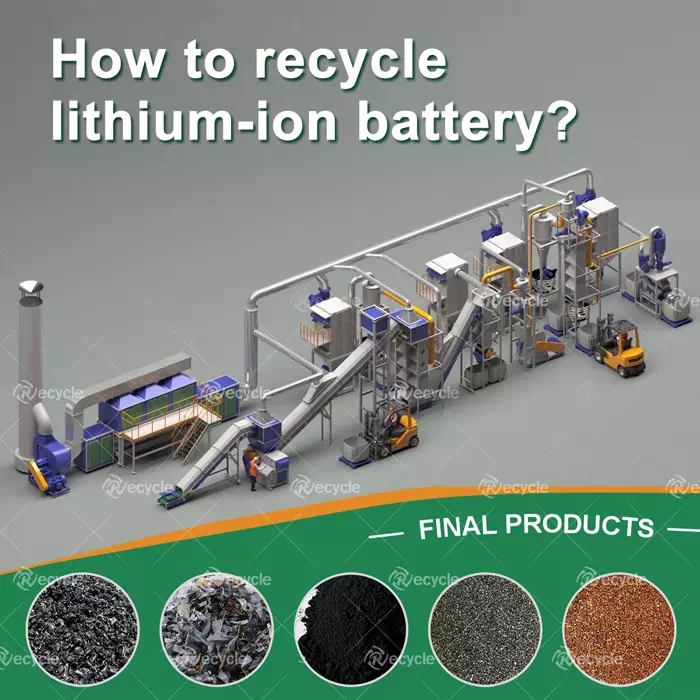

With the rapid development of electric vehicles, a large number of end-of-life lithium-ion batteries have become an urgent problem. In order to realize the effective recycling of these batteries, the related crushing and recycling technology is particularly important.

First of all, the recycling process of waste lithium batteries mainly includes the following steps:

The shredder will collect the waste lithium batteries for initial crushing, the battery shell, positive and negative pole pieces and other separation. The crusher further crushes the shredded material to reduce its size to below 20mm. Through drum screening, magnetic separation and other processes, the black powder, copper and aluminum and other valuable metal components are separated. The separated valuable metals are further extracted by grinding, specific gravity sorting, electrostatic sorting and other deep separation techniques. In addition, the dust generated is treated by pulse dedusting, spray tower adsorption, etc. to ensure that it meets the emission standards.

This process can efficiently recycle the positive and negative electrode materials, copper and aluminum and other valuable metals in lithium batteries, and realize the recycling of resources. At the same time, through negative pressure operation and exhaust gas purification measures, also effectively avoid environmental pollution.

Henan recycle EV's lithium-ion battery crushing and recycling technology is already mature, which not only can efficiently recycle the valuable metals in the battery, but also can minimize the environmental impact. Henan recycle EV has already provided perfect lithium battery recycling solutions for many customers around the world. With its rich experience, first-class technical equipment and attentive after-sales service, it has been praised and trusted by customers.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou