News

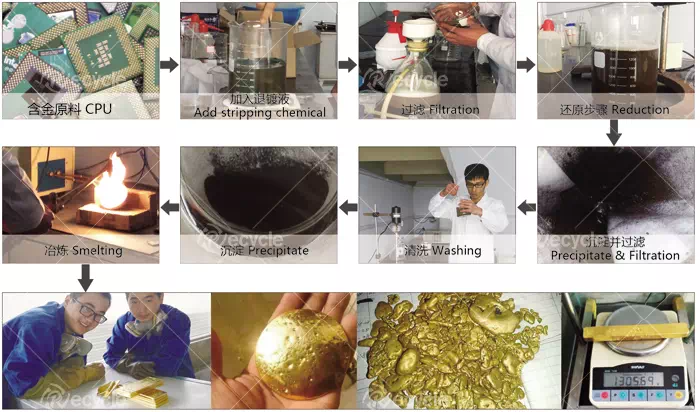

E-waste gold refining and extraction machine

Time:2024-07-17 15:02:35

With the popularization of electronic products, the amount of e-waste is also increasing rapidly. These wastes contain a large amount of precious metals, such as gold, silver, palladium, etc. These precious metals can be efficiently extracted and recovered through professional recycling equipment and advanced processes. In this article, we will introduce the main equipment and process flow of e-waste recycling in detail.

The first step of e-waste recycling is to classify and sort the waste. The main goal is to extract components that contain high concentrations of precious metals, such as chips, circuit boards, etc. The following equipment is typically used for this process:

Disassembler: disassembles e-waste circuit boards and other waste materials.

Crusher: crushes the material to a smaller particle size.

Mills: Grinds the material into a fine powder to increase the efficiency of chemical leaching.

Magnetic Separator: Separates ferrous and non-ferrous materials by utilizing magnetic differences.

Eddy current separator: separates non-ferrous and non-ferrous materials by electromagnetic induction.

Acid leaching tanks: use a strong acid solution (such as aqua regia) to soak crushed materials and dissolve precious metals.

Solvent extraction equipment: extract metal ions through organic solvents to further purify the metal solution.

Electrolysis: Utilizes the electrolysis process to reduce the metal ions in solution to pure metal.

Electrolysis tank: Through the process of electrolysis, metal ions are reduced to metal and deposited on the cathode.

Smelting Furnace: The metal obtained from electrolysis is smelted at a high temperature to remove impurities and obtain high-purity metal.

SUNY GROUP after research and development based on this equipment integrated it into a complete e-waste recycling production line, realizing the whole process of automated recycling from sorting, crushing, and leaching to smelting. Such a production line not only improves recycling efficiency but also ensures the safety and environmental protection of the operation.

If you have more interest in this specific equipment or process or need more detailed information, please feel free to contact us!

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou