News

Recycling and Reuse of PV Panels Machine

Time:2025-01-14 15:26:14

As PV panels typically have a lifespan of 25 to 30 years, the efficient recycling of their materials, especially precious metals and other reusable materials, has become a key challenge for the industry as a large number of panels enter the disposal phase.

Firstly, panels contain a variety of materials, including aluminum bezels, glass, silicon wafers, power boxes, etc. The recycling process requires the separation of these different materials, which requires highly sophisticated recycling technologies. Secondly, the dismantling process of PV panels is very complex, and many components need to be handled carefully to avoid damage, especially the precious metals (e.g., gold, silver, palladium, etc.) in them, which have a low content but high recycling value. As a result, traditional manual dismantling or inefficient recycling techniques struggle to keep up with demand.

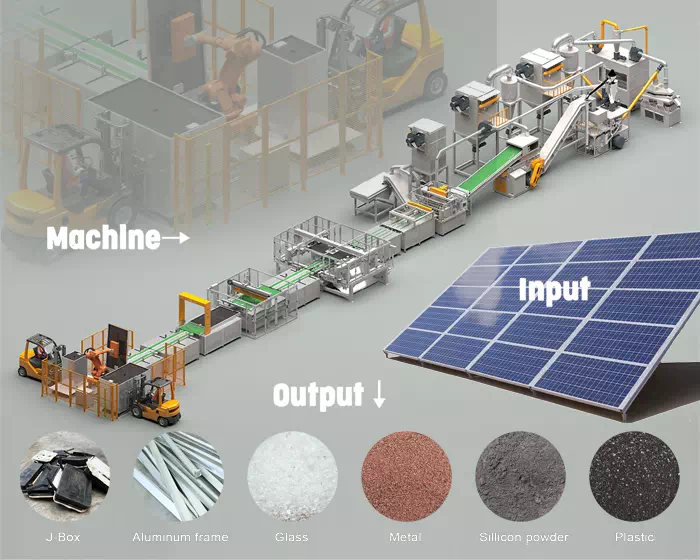

Fully Automated Solar Panel Recycling Line

To address these challenges, Henan Recycle's professional PV panel recycling machines have been created. Through automation and precision technology, the recycling machines are able to complete the dismantling and sorting of PV panels efficiently and quickly, improving recycling efficiency and reducing operating costs. For example, fully automated dismantling machines can automatically dismantle aluminum frames, glass panels, power boxes, and other components of PV panels through precise control systems, and pre-treat these materials to provide convenient recycling for the subsequent recycling work. Compared with manual dismantling, the automated machine reduces human errors and dangers while increasing dismantling speed and precision.

There is a wide range of PV panel recycling machines, covering all aspects of the process from dismantling to sorting and recycling. Common recycling equipment includes fully automated dismantlers, crushers, pulverizers, and separators. Fully automatic dismantlers can remove aluminum frames, glass, and power boxes from PV panels, reducing the risk of manual dismantling and increasing processing speed. Crushing and milling equipment further processes the dismantled material to make it suitable for subsequent sorting. Sorting equipment, in turn, accurately separates metallic and non-metallic materials through the use of magnetic, electrostatic, or airflow separation technologies, further extracting metallic materials and precious metals, which can then be reused to produce new photovoltaic panels or other products.

As the photovoltaic industry continues to grow, the number of discarded PV panels is also increasing rapidly, and the market demand for PV panel recycling machines is climbing. In the future, with the improvement of environmental awareness and the continuous progress of recycling technology, PV panel recycling will become an important part of resource recycling. The recycling equipment on the market will become more and more intelligent and automated, while the recycling efficiency and environmental performance will be further improved. It is expected that with the support of policies and the development of the industry, the market for PV panel recycling equipment will continue to expand and become an important force in promoting a green economy and sustainable development.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou